When I decided to build the large Legos out of foam, one design challenge was how I was going to create all of the studs (cylindrical knobs on the tops of Legos). It would be hard to cut out each of those shapes by hand using the hot knife. I thought of several different strategies—buying foam pool noodles and slicing them into small segments, creating a metal ‘cookie cutter’ type tool, etc. I looked online for some suggestions and ran across an idea of creating a custom-shaped hot knife, using an old soldiering iron and copper wire.

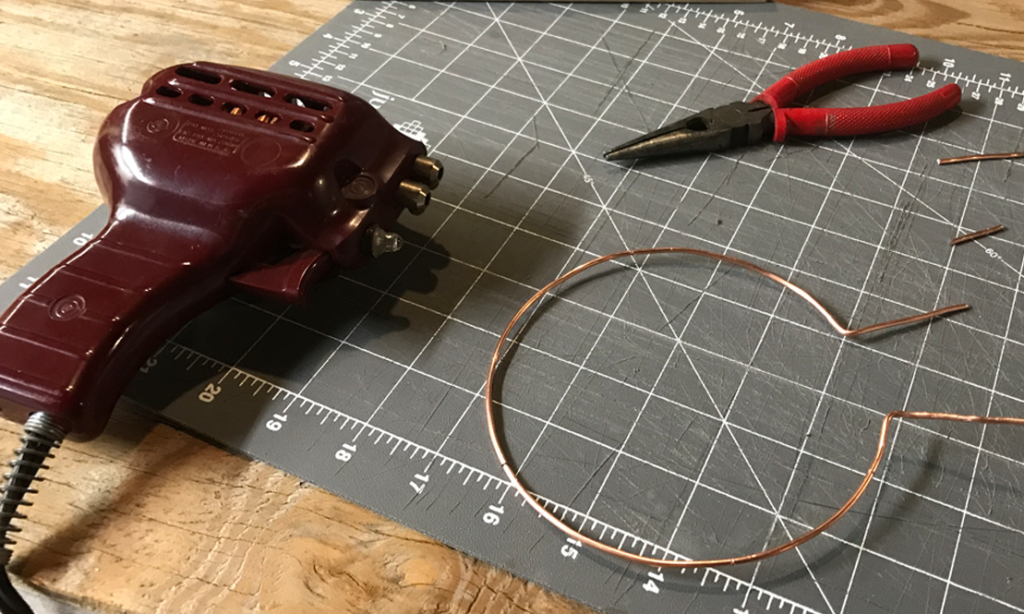

Fortunately, I had my dad’s soldiering gun, which had interchangeable tips. Each tip had two leads that fit into the main body of the gun/handle to allow electricity to pass through the tip, causing heat. I would create my own attachment that fit into soldiering gun.

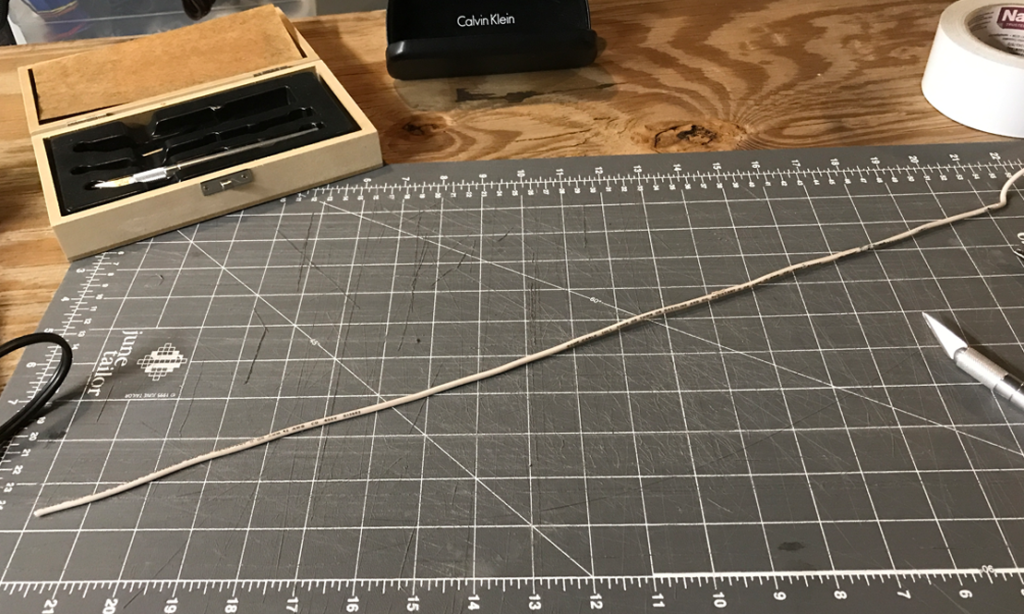

To do this, I removed the tip from the soldering iron and got a long length of copper wire.

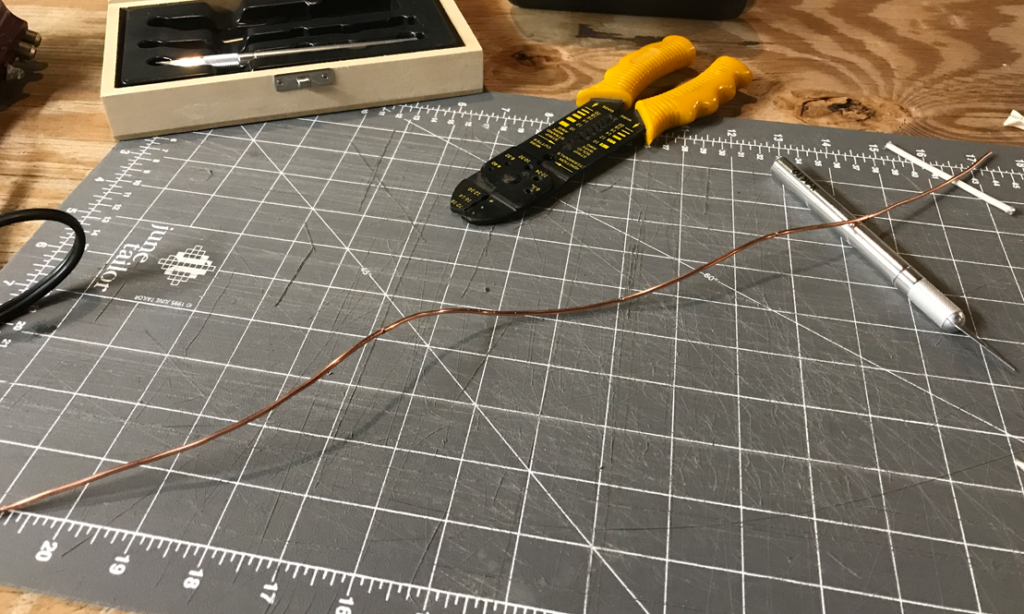

I then straightened the wire and removed the outer covering.

From there, I bent the wire into a circle, with the ends protruding in a formation that would line up with the soldiering gun.

I attached it, as I might attach a normal tip, and voilà! I had a ‘hot knife’ in the shape of a Lego stud. I call it, “The Studmaker.” 🙂

To use it, I pushed the trigger and let the wire heat up. Once it was hot, it passed through the foam smoothly.

From there, I began to crank out stud after stud which I could then attach to the other foam pieces to create the Legos.